Home / R&D

R&D Mission

Committed to designing high quality, high efficiency, high value products and provide partners with the best quality power solutions.

ISO 9001 Certified

Tiger Power is certified by ISO 9001 quality management system, We ensure product quality and provide the best service for our partners.

Consider Tiger Power Your Best Choice

Enthusiastic as well as professional in cutting-edge techniques, Tiger Power makes our customers always stay competitive.

UNDERSTAND YOUR NEEDS

Meet Your Demands

Supported by our abundant application-oriented knowhow, Tiger Power’s RD engineers are always able to define and develop power supply units which meet market demand without compromise.

Take Care of The Challenge

Backed up by Tiger Power’s extensive design database, our engineers can always precisely optimize circuitry design as well as component selection.

Innovate Digital Power Supply

Enhanced by DSP or MCU, digitized power supply units therefore offer users a lot more benefits compared to classic solutions.

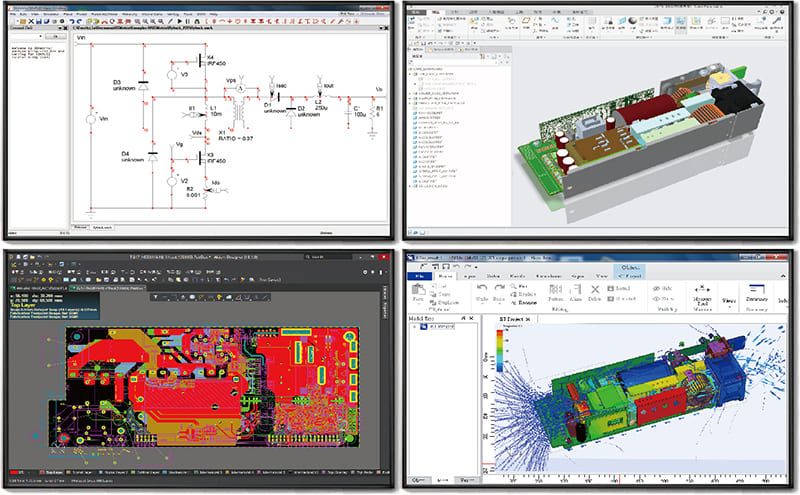

Go Over Simulations

In EVT stage, we use a series of state-of-the-art software tools to largely improve design quality as well as shorten the development cycle.

Select Equipment of Precision

The adoption of the best quality equipment is the key for our engineers to select the right components enclosed in Tiger Power’s PSUs.

Go Over Simulations

We use a series of state-of-the-art software tools to largely improve design quality as well as shorten the development cycle.

-

Electronic Design (IsSpice)

-

3D Mechanical Simulation (PTC Creo 6.0)

-

PCB Layout (Altium Designer 18)

-

Thermal Simulation (6sigmaET , CFD)

6 Processes to Verify Product Quality

Electronic function verification

- Input power & efficiency test

- Input Current & efficiency test

- No load power consumption test

- Line regulation test

- Load regulation test

- Dynamic (transient) regulation test

- Peak load test

- Ripple & noise test

- Inrush current test

- Overshoot & undershoot test

- Power timing sequence test

- Hold-up time test

- Turn on time test

- Switching on time test

- Power signal test

- Rise time test

- Over current protection test

- Over voltage protection test

- Short circuit protection test

- Brownout & brownout recovery

- On/off cycling test

- Storage test

Thermal verification

- Thermal analysis test

- Over temperature protection test

Stress verification

- Mean time between failure

- Bmax test

- Component stress test

- Safe operating area test

EMC verification

- Electrical fast transient test

- Lightning surge test

- Electrostatic discharge test

- Electromagnetic interference test

- Harmonic current test

- Disturbance ac power line test

Safety verification

- Hi-pot test (Dielectric strength)

- Insulation resistance test

- Grounding continuity test

- Touch current test

Reliable verification

- Highly accelerated life test

- Environment derating margin

- Vibration test

- Mechanical shock test

- Drop test

- Thermal shock test

- Thermal cycling test

Reliable Verification

Our design solutions follow a multi-disciplinary approach aligned with regulations. The power supply can be verified by testing laboratories to comply with international safety regulations according to customers’ needs. For example:CE, CB, TÜV/TÜV-GS, UL/cUL, NOM, RCM, EAC, PSE, KC, PSB, CCC, CQC, BIS, BSMI, FCC, RoHS, etc.

Europe CE

IECEE CB

Germany TÜV GS

USA & Canada UL

Mexico NOM

Australia & New Zealand RCM

CU EAC

JAPAN PSE

Korea KC

Singapore PSB

China CCC

China CQC

India BIS

Taiwan BSMI

FCC

RoHS

Satisfy Your Needs

More than 40 years power supply design experience in various industries, we know how to provide partners with tailored power solution to fit their needs.