Home / FAQ / TECHNICAL ARTICLES / HOW TO CHOOSE AN AC-DC POWER SUPPLY?

How to Choose an AC-DC Power Supply?

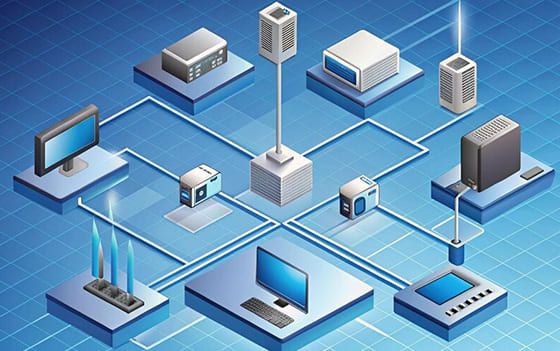

AC-DC power supplies play a vital role in modern electronic systems by converting alternating current (AC) into direct current (DC) to deliver stable power to various devices. Whether used in industrial automation, consumer electronics, or medical equipment, selecting the right power supply is essential. Given the wide range of options available, understanding key parameters and performance characteristics can help engineers and users identify the ideal solution for their specific needs. This article will discuss the critical factors to consider when choosing an AC-DC power supply and provide helpful guidelines for making the best choice.

1. Input Voltage and Frequency

When choosing an AC-DC power supply, it’s crucial to understand its input specifications to ensure it meets the needs of your application. The typical input voltage range for AC power supplies is 90 to 264Vac, which covers the requirements of most global markets. Users should verify whether the input voltage range of the power supply aligns with the target market and application conditions. For instance, Japan operates at a lower input voltage of 100Vac, while countries like the UK, Canada, and the US use a higher input voltage of 240Vac. Additionally, the input frequency is another important consideration, with most power supplies supporting 50Hz or 60Hz to ensure stable operation across different power grids. When selecting an AC-DC power supply, it’s essential to carefully evaluate the input voltage range and frequency to ensure compatibility with various environments.

2. Output Voltage

The output specifications are one of the key factors when selecting an AC-DC power supply. Users should choose a power supply based on the required output voltage (V), current (A), and rated power (W). Common standard output voltages include 5Vdc, 12Vdc, 18Vdc, 24Vdc, 36Vdc, 42Vdc, 48Vdc, and 54Vdc. It’s important to select the appropriate output voltage based on the specific industry application. If the system’s load requires a non-standard output voltage, users can contact us to customize a power supply that meets their specific needs.

The following are common internal power voltage ranges for electronic devices, which may vary depending on design requirements:

.Server: 5Vdc / 12Vdc / 48Vdc

.Storage: 12Vdc

.Firewall/UTM: 5Vdc / 12Vdc / 24Vdc

.100/400 GbE Switch: 12Vdc / 24Vdc

.Non PoE Switch: 12Vdc

.PoE Switch: 54Vdc

.5G Equipment: 12Vdc / 54Vdc

.IP-PBX: 12Vdc / 48Vdc / 54Vdc

.Telecom: 48Vdc

.PC/IPC: 12Vdc

.Industrial Equipment: 24Vdc / 36Vdc / 48Vdc

.Banking Device: 24Vdc / 48Vdc

.Medical Testing Device: 12Vdc / 24Vdc

.Printing Machine: 24Vdc / 48Vdc

.POS: 12Vdc / 24Vdc

.Sewing Machine: 100-240V AC / 24Vdc

.Gaming Machine: 12Vdc / 24Vdc

.Display Device: 5Vdc / 12Vdc / 24Vdc

3. Selecting Current and Power

When choosing an AC-DC power supply, it is essential to ensure that the output current can meet the device’s power requirements. Insufficient power supply can adversely affect the device’s normal operation. The required output power (unit: watts) is a key factor in selecting the power supply. The peak power consumption of the load determines the power supply’s rating. Power (W) is the basic unit of electricity, calculated using the formula W = V × A, where W is power, V is voltage, and A is current. Therefore, when selecting a power supply, users should determine the required power based on the expected voltage and current demands of the device.

To ensure stable system operation, the chosen power supply rating should exceed the maximum load requirement without being excessively high to avoid unnecessary costs and bulk. It is generally recommended to select a power supply with a rated power 20% to 30% higher than the peak power demand of the device. This provides a buffer to accommodate potential load variations and unexpected conditions. If the rated power of the supply is less than the load requirement, it may lead to shutdowns or incorrect output voltage, impacting the stability of the system’s operation.

It is worth noting that we offers AC-DC power supply designs capable of providing high peak power for short durations. This feature allows the power supply to meet sudden high load demands while minimizing size and cost. Therefore, selecting a power supply with peak power capabilities based on specific application needs can be an effective solution.

4. Application Environment Requirements

When selecting an AC-DC power supply, the conditions of the application environment are crucial factors to consider. Different working environments impose various requirements on the design and operation of the power supply. Users need to choose a suitable power supply based on the specific application scenarios to ensure stable system operation. Here are some key environmental requirements:

(1) Temperature Range

The operating temperature range of the power supply is one of the critical factors affecting its performance. Most AC-DC power supplies operate within a temperature range of -10°C to +50°C. However, in extreme environments (such as very cold or hot conditions), the performance of the power supply may be affected by temperature fluctuations. In very cold conditions, capacitor components can freeze, impacting startup. In hot environments, the performance of electronic components or semiconductors may degrade, resulting in reduced output load current and power. To address high temperatures, some power supplies utilize forced air or liquid cooling to maintain maximum output power by cooling the electronic components.

(2) Humidity and Protection Rating

In high humidity or outdoor environments, power supplies must have adequate protection to prevent moisture or dust from affecting their operation. Choosing power supplies with appropriate protection ratings (such as IP65 or higher) can safeguard internal circuits from moisture and dust, ensuring stable operation in harsh conditions.

(3) Vibration and Shock

In high-vibration or frequently impacted environments (such as industrial sites or transportation), power supplies must demonstrate good resistance to vibration and shock. Power supplies that comply with IEC 60068 or MIL-STD-810G standards can ensure stable performance under these harsh conditions.

(4) Altitude

High-altitude environments can affect the heat dissipation and insulation performance of power supplies. As altitude increases, air density decreases, reducing cooling efficiency, which necessitates specially designed power supplies. Additionally, internal insulation must be enhanced to prevent breakdowns at low pressure.

(5) Electromagnetic Interference (EMI)

In environments with complex electromagnetic conditions, the ability of power supplies to resist electromagnetic interference (EMI) is crucial. Selecting power supplies that meet EMC standards can minimize the impact of EMI on equipment operation, ensuring system stability.

(6) Operating Environment Specifications

The operating environment of the power supply affects its performance and selection. In low-temperature environments, the temperature coefficient of capacitors can lower capacitance, impacting output load current. Conversely, in high-temperature conditions, the maximum operating temperature of internal components can limit output power. Some power supplies can use forced airflow to cool internal components, thereby increasing the maximum rated output power. These derating factors and cooling technologies should be considered during power supply selection.

(7) Application Domain Requirements

Specific application domains such as medical, aerospace, and military have higher demands for the reliability, safety, and stability of power supplies. For example, power supplies in the medical field must comply with IEC 60601 standards to ensure insulation performance and low leakage currents, while military applications must adhere to MIL-STD standards to address challenges in extreme environments.

5. Size and Space Configuration

When selecting the appropriate power supply, users should evaluate the size requirements of the application device and determine whether to use an Open Frame PSU, Enclosed PSU, or Adaptor. This ensures that the power supply’s size and design align with the overall configuration of the device, enhancing efficiency and flexibility.

(1) Open Frame PSU

Open Frame PSUs are designed as bare boards using printed circuit boards (PCBs) and are typically applied in embedded systems. This compact design allows these power supplies to be flexibly integrated into various devices, making them particularly suitable for applications with limited space.

(2) Enclosed PSU

Enclosed PSUs provide better protection and are suitable for environments that require stable operation. These power supplies typically feature robust housing designed to effectively prevent dust, moisture, and other environmental factors from affecting performance. They can be utilized in a variety of applications, such as data centers, industrial automation equipment, and various electronic products.

(3) Adaptor

Adaptors are portable power supplies focused on convenience, commonly used for external devices like laptops or small electronic products. They are relatively lightweight and compact, making them easy to carry. When selecting an adaptor, it is essential to consider whether its output voltage and power meet the device’s requirements to ensure proper operation.